August 2008

Field Crops 28.47-59

Fall Management Decisions and Practices for Corn

Joe Lauer, Corn Agronomist

PDF Version

Growing Season Update

The 2008 production year has been one of the coolest on record. Growing degree unit

accumulation is tracking about 300 GDUs behind schedule. Temperature drives the

vegetative (V) developmental stages of the corn life cycle, but has less influence

during the reproductive (R) developmental stages (Table 1). The number of days from

silking (R1) to maturity (R6) ranges from 55 to 60 days. A farmer benchmark to gauge

the season is "To be dented by Labor Day." About 26-28 days remain for the crop

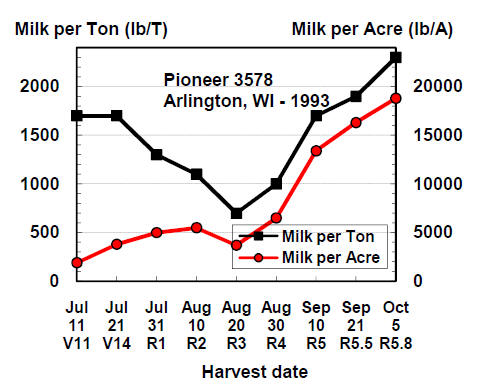

to mature. Optimum silage yield and quality occurs around 50% Kernel Milk (R5.5)

(Figure 1).

|

Table 1. Relationship between corn kernel growth stage and development.

|

|

|

|

Growing Degree Units

(GDUs) to Maturity

|

Percent of

Maximum Yield

|

Moisture

Content (%)

|

|

Stage

|

Calendar Days

to Maturity

|

Southern

Wisconsin

|

Northern

Wisconsin

|

Grain

|

Whole

Plant

|

Grain

|

Whole

Plant

|

|

R1- Silk

|

55-60

|

1100-1200

|

950-1050

|

0

|

50-55

|

---

|

80-85

|

|

R2 - Blister

|

45-50

|

875-975

|

800-900

|

0-10

|

55-60

|

85-95

|

80-85

|

|

R3 - Milk

|

37-42

|

750-850

|

700-800

|

15-25

|

60-65

|

75-85

|

77-82

|

|

R4 - Dough

|

31-36

|

600-700

|

550-650

|

30-50

|

65-75

|

60-80

|

75-80

|

|

R5 - Dent

|

26-28

|

425-525

|

400-500

|

60-75

|

75-85

|

50-55

|

70-75

|

|

R5.5 - 50% Kernel milk

|

10-15

|

200-300

|

175-275

|

90-95

|

100

|

35-40

|

65-70

|

|

R6 - Maturity

|

0

|

0

|

0

|

100

|

95-100

|

25-35

|

55-65

|

Figure 1. Corn silage yield and quality changes during development.

In-season guidelines for predicting corn silage harvest date

- Note hybrid maturity and planting date of fields intended

for silage.

- Note tasseling (silking) date. Kernels will be at 50% kernel

milk (R5.5) about 42 to 47 days after silking.

- After milkline moves, use kernel milk triggers to time

corn silage harvest (Figure 2). Use a drydown rate of 0.5% per day to predict date

when field will be ready for the storage structure (Table 2). See

http://www.uwex.edu/ces/ag/silagedrydown/

- Do final check prior to chopping.

|

Table 2. Kernel milk stage "Triggers" for timing silage harvest.

|

|

Silo Structure

|

Ideal Moisture

Content

|

Kernel Milk

Stage "Trigger"

|

|

|

%

|

%

|

|

Horizontal bunker

|

70 to 65

|

80

|

|

Bag

|

70 to 60

|

80

|

|

Upright concrete stave

|

65 to 60

|

60

|

|

Upright oxygen limiting

|

50 to 60

|

40

|

|

"Trigger": kernel milk stage to begin checking moisture

Silage moisture decreases at an average rate of 0.5% per day during September

|

Selecting Corn Hybrids

PPast hybrid trials indicate that the average yield difference between the highest

and lowest yielding corn hybrid in a trial is 70 bu/A. Your challenge is to predict

performance the next growing season. Depending upon how you select hybrids, yield

gains up to 12 bu/A can be achieved over an "average" hybrid.

When choosing hybrids for the next growing season:

- Select hybrids using multi-location average data. Consider single location results

with extreme caution.

- Evaluate consistency over years and other trials. Be wary of hybrids that are not

top performers in all trials.

- Buy the traits you need (Table 3, aslo see

spreadheet). Traits protect yield, they do not add to yield. Can you grow corn

the "old-fashioned" way?

- Rotation

- Weed control

- European Corn Borer

- Every hybrid must "stand on its own" for performance (Table 4).

|

Table 3. Economic advantage ($/A) of Hybrid A or (Hybrid B).

Seed price difference = $50 bag: A = $150, (B) = $200

|

|

Yield advantage

|

Corn Price ($/bu)

|

|

Hybrids

|

(bu/A)

|

$1.00

|

$2.00

|

$3.00

|

$4.00

|

$5.00

|

$6.00

|

$7.00

|

|

|

(14)

|

$8

|

($6)

|

($20)

|

($34)

|

($48)

|

($62)

|

($76)

|

|

|

(12)

|

$10

|

($2)

|

($14)

|

($26)

|

($38)

|

($50)

|

($62)

|

|

|

(10)

|

$12

|

$2

|

($8)

|

($18)

|

($28)

|

($38)

|

($48)

|

|

A < (B)

|

(8)

|

$14

|

$6

|

($2)

|

($10)

|

($18)

|

($26)

|

($34)

|

|

|

(6)

|

$16

|

$10

|

$4

|

($2)

|

($8)

|

($14)

|

($20)

|

|

|

(4)

|

$18

|

$14

|

$10

|

$6

|

$2

|

($2)

|

($6)

|

|

|

(2)

|

$20

|

$18

|

$16

|

$14

|

$12

|

$10

|

$$8

|

|

A = (B)

|

0

|

$22

|

$22

|

$22

|

$22

|

$22

|

$22

|

$22

|

|

|

2

|

$24

|

$26

|

$28

|

$30

|

$32

|

$34

|

$36

|

|

|

4

|

$26

|

$30

|

$34

|

$38

|

$42

|

$46

|

$50

|

|

|

6

|

$28

|

$34

|

$40

|

$46

|

$52

|

$58

|

$64

|

|

A > (B)

|

8

|

$30

|

$38

|

$46

|

$54

|

$62

|

$70

|

$78

|

|

|

10

|

$32

|

$42

|

$52

|

$62

|

$72

|

$82

|

$92

|

|

|

12

|

$34

|

$46

|

$58

|

$70

|

$82

|

$94

|

$106

|

|

|

14

|

$36

|

$50

|

$64

|

$78

|

$92

|

$106

|

$120

|

Remember that you don't know what weather conditions (rainfall, temperature) will

be like next year. Therefore, the most reliable way to predict hybrid performance

next year on your farm is to consider past performance over a wide range of locations

and climatic conditions.

|

Table 4. Relative performance among corn hybrid "Families" compared to the normal

line grown in the same trial

|

|

Family

|

Specialty Trait

|

N

|

Grain

yield

|

Grain

moisture

|

Lodging

|

|

|

|

|

Bu/A

|

%

|

%

|

|

A12

|

DDBT418

|

6

|

1

|

1

|

2

|

|

A12

|

MMon810

|

6

|

20

|

1

|

-3

|

|

A12

|

MMonGA21

|

25

|

2

|

0

|

-1

|

|

B99

|

MMon810

|

3

|

15

|

3

|

-2

|

|

B99

|

MMon810+T25

|

3

|

-2

|

1

|

-1

|

|

C284

|

MMon810

|

24

|

17

|

1

|

-1

|

|

C284

|

MMon810+IT

|

6

|

-3

|

0

|

-1

|

Recommended Practices v. Trends v. "Snake Oils"

TThe 2008 corn production and marketing season is unique. On one hand, it is the

most expensive corn crop ever planted, and on the other, it has the potential to

be the most profitable due to strong market price. If input costs continue to increase,

profit margin will be back to previous years, except with more risk.

So for this year, we have strong prices relative to input costs, thus any production

increase can be more easily paid for. We have to be careful about practices that

can be recommended versus practices that intuitively may trend to greater yields,

but are not statistically significant and thus cannot be recommended. These trends

produce responses too small to be statistically significant.

In agronomic research it is very difficult to detect treatment differences less

than 5%. So in a 200 bu/A yield environment, that means at least 10 bu/A is required

before statistical differences can be detected. What about trends less than 10 bu/A?

At today's prices a difference of even 5 bu/A can pay for many inputs.

Every year in Wisconsin, products are touted to producers as being the cure for

crop production and economic woes. The adage "If it sounds too good to be true,

then it probably is." How do you know whether a particular product is a viable

fertilizer and supplies crop nutrients, or has some proven effect on soil that will

improve productivity? The standard advice is to demand unbiased research results

that document all claims, and to discount testimonials. If well-documented research

isn't available, then be suspicious of claims. An electronic compendium is available

that provides information on non-traditional materials marketed for use in crop

production in the north central region of the USA. It is a collection of research

abstracts and reports released by scientists in State Agricultural Experiment. See

the website: http://extension.agron.iastate.edu/compendium/index.aspx