Frost

Originally written February 1, 2006 | Last updated February 23, 2014

Frost can occur at any time during the growing season. Frost events in

July and August can occur in northern Wisconsin, although these events

are rare. Most of the time farmers deal with early- or late-season

frosts that impact spring plant establishment or affect yield and

harvest timing in the fall.

Early-season frost

Corn plants will not be killed by frost unless temperatures get cold

enough to kill the growing point that is 3/4 of an inch below the soil

surface. So corn that has not emerged typically is well insulated from

frost damage.

So corn that has not emerged typically is well insulated from

frost damage.

Frost should not be a problem with corn until the growing point moves aboveground around V5 to V6. Farmers and agronomists usually do not worry about frost at these

early stages of development. Early frost can have an impact on grain yield, but the trade-off between planting date impact on yield is greater than for frost damage

impact on yield. Delayed planting further impacts profitability due to greater moisture and consequential drying costs.

Symptoms of frost damage will start to show up about 1 to 2 days after a frost.

Symptoms are water soaked leaves that eventually turn brown. After 3 to 4 days watch

for new green leaves emerging n the whorl. If new leaves are not emerging check

the growing point for discoloration. Any deviation from a white, cream or light

yellow color indicates that the growing point is killed.

Experiments were conducted in 2001, 2002, 2003, 2004, and 2005 to measure the impact of early defoliation on corn grain yield. Clipping treatments were applied

at V2, V4 and V6. Clipping treatments consisted of cutting the plant at ground level with a scissors. Plants in the control treatment were not clipped. In another

treatment, all plants in the plot were clipped. In another set of treatments, half of the plants were clipped in 2-, 4-, and 8-plant patterns. For example in the

2-plant pattern, the first 2 plants in the row were not clipped, the next 2 plants were clipped at ground level, the next 2 plants were not clipped, and so on.

Although these treatments do not fully simulate the light frost damage that recently occurred on corn over the last couple of evenings, they do provide some guidance

on what a hard frost might do that completely defoliates the plant without killing it. Figure 1 describes the impact of complete defoliation on corn grain yield

at the V2 stage of development. When all plants were clipped, grain yield decreased 17 bu/A from 210 to 193 bu/A (8%). When half of the plants were clipped in various

patterns, grain yield was not affected; the trend was a decrease of 8 to 9 bu/A (4%).

These data indicate that frost early in development has relatively little impact on corn grain yield. If all of the leaves are removed from every plant in the field

at the V2 stage of development and plants are not killed, then the expectation is that grain yield would decrease up to 8%. If the recent frosts were hard enough

to kill plants then use the publication UWEX 3353 for guidance on whether or not to keep a stand and what to look for when

assessing plant health.

Figure 1. Impact of clipping corn leaves at V2. Experiments were conducted in 2001, 2002, 2003, 2004, and 2005 at Arlington, WI. Treatments consisted of clipping

at ground level (or not clipping) consecutive plants in 2-, 4-, 8-, and all-plant patterns.

Late-season frost

Freezing temperatures before physiological maturity will damage corn. Maturity in corn occurs when kernels form a black layer at the

kernel tip, grain will be at approximately 30 to 35 percent moisture.

After maturity, no additional dry matter will be accumulated in the

seed. In addition to creating quality problems, premature frost will

reduce the yield of dry grain.

Freezing temperatures before physiological maturity will damage corn. Maturity in corn occurs when kernels form a black layer at the

kernel tip, grain will be at approximately 30 to 35 percent moisture.

After maturity, no additional dry matter will be accumulated in the

seed. In addition to creating quality problems, premature frost will

reduce the yield of dry grain.

Will corn mature before a killing frost?

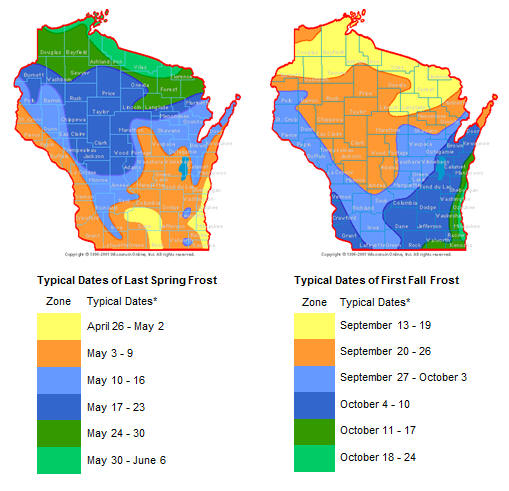

Typically in a normal year, corn should be "silking at the end of

July and denting on Labor Day." After corn silks, it normally takes

about 55 to 60 days (1000 to 1200 GDUs)for it to mature (Table 1).

Normally during September, growing degree units in Wisconsin accumulate at the rate

of 12 to 19 units per day for a total accumulation of 400 to 450 units (Table 2).

Likelihood of a 32 ° F freeze by September 20 is 3 years out of 5 in northern, and

1 year out of 5 in southern Wisconsin.

|

Table 1. Required growing degree units between corn development stages and maturity

(black layer).

|

|

Corn

|

Relative maturity zone (days)

|

|

development

|

85-90

|

95-105

|

110-120

|

|

stage

|

Growing degree units

|

|

R1 (silking)

|

1000

|

1100

|

1200

|

|

R2 (blister)

|

800

|

880

|

960

|

|

R3.5 (late milk / early dough)

|

600

|

660

|

720

|

|

R4.5 (late dough / early dent)

|

400

|

440

|

480

|

|

R5 (dent)

|

200

|

220

|

240

|

|

R6 Maturity (black layer)

|

0

|

0

|

0

|

|

Harvest (kernel moisture at 25%)

|

150

|

150

|

150

|

|

derived from Carter, 1991

|

|

Table 2. Corn growing degree unit accumulation in Wisconsin.

|

|

|

North

|

|

South

|

|

Month

|

Daily

|

Monthly

|

Total

|

|

Daily

|

Monthly

|

Total

|

|

|

Growing degree units

|

|

May

|

8-11

|

300

|

300

|

|

10-13

|

350

|

350

|

|

June

|

11-17

|

400

|

700

|

|

13-20

|

500

|

850

|

|

July

|

17-20

|

575

|

1275

|

|

20-23

|

650

|

1500

|

|

August

|

20-17

|

575

|

1850

|

|

23-19

|

650

|

2150

|

|

September

|

17-12

|

400

|

2250

|

|

19-13

|

450

|

2600

|

|

October

|

12-8

|

300

|

2550

|

|

13-10

|

350

|

2950

|

|

derived from Mitchell and Larsen, 1981

|

Use Tables 1 and 2 to determine the likelihood that a field will mature. For example,

if on September 1, your field is at R3.5 (late milk / early dough) and you are in

a 95-105 relative maturity zone, it will take about 660 growing degree units to

mature the crop before it is killed by a frost. Since corn is usually killed in

3 out of 5 years by September 20 the field in all likelihood will accumulate about

300 to 380 growing degree units and be at the early dent to dent stage of development

when it is killed by a frost.

Temperatures required to kill corn plants

For fields that only had light frost damage, it is too early to harvest. Growing

conditions may improve during September allowing the crop to mature and produce

reasonable grain and silage yields.

Corn is killed when temperatures are near 32 F for a few hours, and when temperatures

are near 28 F for a few minutes (Carter and Hesterman, 1990). A damaging frost can occur when temperatures are

slightly above 32 F and conditions are optimum for rapid heat loss from the leaves

to the atmosphere, i.e. clear skies, low humidity, no wind. At temperatures between

32 to 40 F, damage may be quite variable and strongly influenced by small variations

in slope or terrain that affect air drainage and thermal radiation, creating small

frost pockets. Field edges, low lying areas, and the top leaves on the plant are

at greatest risk. Greener corn has more frost resistance than yellowing corn.

Symptoms of frost damage will start to show up about 1 to 2 days after a frost.

Frost symptoms are water soaked leaves that eventually turn brown. Because it is

difficult to distinguish living from dead tissue immediately after a frost event,

the assessment should be delayed 5 to 7 days.

Silage moisture drydown

Corn silage should be harvested at the appropriate moisture content for the type

of silo in which it will be stored (Table 3). If corn is frosted prior to 50% kernel milk,

the moisture content of corn may be too high to be properly ensiled. However, during

the drydown period, dry matter yield will decrease due to leaf loss, plant lodging

and ear droppage. Thus, a trade-off exists between moisture and yield.

For corn silage frosted prior to the dent stage, the moisture content will be too

high for successful ensiling. The silage crop should be allowed to dry in the field

for several days and moisture content should be monitored. For corn frosted during

the dent stage, harvest should begin quickly to prevent yield loss as damaged leaves

are shed or break off the plant.

Since mold can occur on the ears before the desired moisture level is reached, harvest

may have to begin immediately. To help control problems with excess moisture, wet

silage can be mixed either with ground grain, straw, or chopped hay to reduce the

overall moisture of the stored silage, The rule of thumb is about 30 pounds of dry

material per ton of silage will be needed to reduce silage moisture one percentage

unit.

Grain quality impact

Late season frost damage can affect grain quality and is directly proportional to

the stage of maturity and leaf tissue killed. Severe impacts on grain quality can

occur at mid-dough, while moderate impacts are seen at the dent stage. By the time

the kernel has reached half milk line only minor impacts will occur to grain quality.

Differences among hybrids, overall plant vigor at the time of frost and subsequent

temperatures will all affect final grain quality.

Handling silage from fields with uneven maturity

Many corn fields in Wisconsin can be uneven for maturity. There is some concern about

harvesting these fields for silage and the potential for mold development. Mold

problems in silage occur when corn is harvested too dry. When harvesting a corn

field differing in maturity handle field sections separately where possible. In

fields where the chopper must move through areas differing in maturity (i.e. low

spots) chop when the majority of the field is at the proper moisture. The immature

spots will be wetter than the rest of the field and might seep in the silo, but

as long as the seepage does not leave the silo, nothing is lost. Fermentation should

be adequate for preservation of the corn silage. However, corn that is too dry might

develop a "hot spot " where mold can develop, thereby increasing the chances

for mycotoxin development.

Harvesting silage at the correct moisture

If the decision is made to harvest the crop for ensiling, the main consideration

will be proper moisture for storage and fermentation. Recommended whole-plant

moisture contents for fermenting corn and producing silage vary for different storage

structures (Table 3). In general, more moisture is required to get good packing

in storage structures that allow easy diffusion of air such as bunkers.

Table 3. Recommended moisture content (%) for corn stored in

various types of storage

structures.

|

|

Upright oxygen limiting silos

|

50-60

|

|

Upright concrete stave silos

|

60-65

|

|

Bag silos

|

60-70

|

|

Horizontal bunker silos

|

65-70

|

|

Roth et al., 1995

|

For many years, corn was harvested for silage at the black layer stage of development.

Lower forage fiber levels, higher digestibility and highest yields were observed

slightly earlier than the black layer stage, and recently this recommendation was

modified to begin corn silage harvesting at 50% kernel milk and be finished by 25%

kernel milk (Wiersma et al., 1993).

Growers often find that corn is too wet and seepage occurs in the silo when corn

is harvested at 50% kernel milk. On average, the recommendation of using kernel milk to predict whole plant moisture

is closely correlated with previous work. For example, at 50% kernel milk whole-pant

moisture equals 63%.

However, the range at 50% kernel milk is 53 to 73% whole plant moisture, with the

majority of the hybrid environments around 70%. Many hybrids grown in Wisconsin

have a "stay-green" trait that improves standability by keeping the stalk

and leaves green while husk leaves turn brown and open allowing the ear too dry.

After a frost the crop will look drier than

it really is, so moisture testing will be critical. Be sure to test whole-plant

moisture of chopped corn to assure yourself that acceptable fermentation will occur.

Use a forced air dryer (i.e. Koster), oven, microwave, electronic forage tester,

NIR, or the rapid "Grab-Test" method for your determination. With the

"Grab-Test" method (as described by Hicks, Minnesota ), a handful of finely

cut plant material is squeezed as tightly as possible for 90 seconds. Release the

grip and note the condition of the ball of plant material in the hand.

- If juice runs freely or shows between the fingers, the crop contains 75 to 85% moisture.

- If the ball holds its shape and the hand is moist, the material contains 70 to 75%

moisture.

- If the ball expands slowly and no dampness appears on the hand, the material contains

60 to 70% moisture.

- If the ball springs out in the opening hand, the crop contains less than 60% moisture.

The proper harvest moisture content depends upon the storage structure, but is the

same for drought stressed and normal corn. Harvesting should be done at the moisture

content that ensures good preservation and storage: 65-70% in horizontal silos (trenches,

bunkers, bags), 60-65% in upright stave silos, and 55-65% in upright oxygen limiting

silos.

Other considerations

Growers should monitor stalk rot of severely defoliated plants which have a good-sized

ear. Photosynthate will be mobilized towards the ear rather than the stalk. This

could weaken the stalk and encourage stalk rot development. These fields may need

to be harvested early to avoid standability problems.

Some growers have expressed concern about nitrate poisoning. If frosted corn is

ensiled at the proper moisture content and other steps are followed to provide good

quality silage, nitrate testing should not be necessary. However, it is prudent

to follow precautions regarding dangers of nitrate toxicity to livestock (especially

with grazing and green-chopping) and silo-gasses to humans when dealing with drought-stressed

corn. Nitrates absorbed from the soil by plant roots are normally incorporated into

plant tissue as amino acids, proteins and other nitrogenous compounds. Thus, the

concentration of nitrate in the plant is usually low. The primary site for converting

nitrates to these products is in growing green leaves. The highest concentration

of nitrates is in the lower part of the stalk or stem, so raising the cutter bar

on a corn silage chopper will leave most nitrates in the field. Nitrate concentration

usually decreases during silage fermentation by one-third to one-half, therefore

sampling one or two weeks after filling will be more accurate than sampling during

filling. If the plants contain nitrates, a brown cloud may develop around your silo.

This cloud contains highly toxic gases and people and livestock should stay out

of the area. The only way to know the actual composition of frosted corn silage

is to have it tested by a good analysis lab.

Calculating the value of normal corn silage

Due to late planting dates and a cooler than normal growing season this year, many

corn fields will probably be harvested for silage. There is even great potential

for corn in these fields to be too immature for proper corn silage harvest. How

should the value of corn silage be adjusted for frosted immature corn? Typical calculation

methods for pricing normal corn silage include:

- Relative feed value of a known forage market.

- Silage ($/T) = 1/4 to 1/2 value of hay

- Silage ($/T) = 6 to 8 times the price of a bushel of corn. If already harvested,

then 10 times.

- Feed replacement or substitution costs

- Use market prices for energy, protein, and digestibility (NEL of corn, soybean meal,

hay)

- Contracted price above the cost of production (280-320 $/A).

A handy spreadsheet for calculating the value of corn silage can be found

at

http://corn.agronomy.wisc.edu/Season/DSS.aspx.

Immature corn silage

For most crops, forage quality and value decreases with maturity, that is fiber

levels increase and digestible energy decreases. Corn is somewhat unique in that

quality increases with maturity. In corn silage most of the digestible energy is

in the grain portion. Immature corn will have a lower proportion of grain in the

silage. Two approaches to consider for calculating the value of immature corn silage

are:

- Reduce the value of immature corn silage by the cost of buying back grain to bring

the grain:stover ratio to a more normal proportion.

- Use MILK2006 to calculate the milk per acre and milk per ton that could

potentially be produced from immature corn silage.

Afuakwa and Crookston (1984) described the grain yield impact of frost at different

stages of development (Table 4). A killing frost at the soft dough stage of development

would result in a grain yield loss of 55% and at least that much grain would be

required to produce normal silage.

|

Table 4. Potential grain yield losses after frost.

|

|

Corn development

|

Killing frost

(Leaves and stalk)

|

Light frost

(Leaves only)

|

|

Stage

|

percent yield loss

|

|

R4 (Soft dugh)

|

55

|

35

|

|

R5 (Dent)

|

40

|

25

|

|

R5.5 (50% kernel milk)

|

12

|

5

|

|

R6 (Black layer)

|

0

|

0

|

|

derived from Afuakwa and Crookston (1984)

|

The relationship between kernel maturity and silage yield and quality is shown in

Table 5. Milk production per acre is 35% less when corn is harvested at the immature

soft dough stage compared to the optimum stage at 50% kernel milk. Milk production

per ton of immature corn silage (soft dough) was 25% lower than the optimum stage

of 50% kernel milk. Thus, the milk production potential would be reduced between

25 and 35% with immature corn harvested for silage. The value of the corn silage

should be adjusted accordingly.

|

Table 5. Relationship between kernel maturity and corn silage yield and quality.

|

Corn

Development

|

Silage

moisture

|

Silage

yield

|

Crude

protein

|

ADF

|

NDF

|

IVD

|

Milk

production

|

|

|

%

|

T/A

|

%

|

%

|

%

|

%

|

lb/T

|

lb/A

|

|

Soft dough

|

76

|

5.4

|

10

|

27

|

53

|

77

|

1600

|

8600

|

|

Early dent

|

73

|

5.6

|

10

|

24

|

48

|

79

|

1900

|

10800

|

|

50% milk

|

66

|

6.3

|

9

|

23

|

45

|

80

|

2100

|

13300

|

|

25% milk

|

63

|

6.4

|

9

|

24

|

47

|

80

|

2000

|

12600

|

|

Black layer

|

60

|

6.3

|

8

|

24

|

47

|

79

|

1950

|

12400

|

|

derived from Wiersma et al. (1993) and Undersander et al. (1993)

|

Corn silage yield and quality changes substantially during the growing season (Table

6). At V11 crude protein was 18% and one ton of silage could produce 1700 lb. of

milk. Like all crops, corn silage quality decreased as the crop approached flowering.

Milk per ton decreased from 1700 lb./T on V11-14, to 1300 lb./T on R1.0 (silking),

and was lowest at R3.0 (Milk) at 700 lb./T. Milk per ton and milk per acre then

increased throughout the remainder of the growing season. During the silking and

milk stages, milk per acre and milk per ton was about 1/3 of the optimum harvest

dates between R5.5 and R5.8.

Table 6. Corn silage yield and quality response to harvest date for Pioneer 3578

during 1993 at

Arlington, WI. Corn was planted on May 11. Derived from Burger and

Hudelson (1993) and

Undersander et al. (1993).

|

Harvest

|

Corn

development

|

Whole plant

moisture

|

Dry matter

yield

|

Crude

protein

|

ADF

|

NDF

|

Milk production

|

|

date

|

stage

|

%

|

T/A

|

%

|

%

|

%

|

lb/T

|

lb/A

|

|

July 11

|

V11

|

92

|

1.1

|

18

|

28

|

49

|

1700

|

1900

|

|

July 21

|

V14

|

90

|

2.2

|

15

|

27

|

50

|

1700

|

3800

|

|

July 31

|

R1.0

|

85

|

3.8

|

12

|

31

|

55

|

1300

|

5000

|

|

August 10

|

R2.0

|

83

|

5.0

|

11

|

33

|

58

|

1100

|

5500

|

|

August 20

|

R3.0

|

84

|

5.7

|

10

|

36

|

65

|

700

|

3700

|

|

August 30

|

R4.0

|

82

|

6.4

|

10

|

33

|

60

|

1000

|

6500

|

|

September 10

|

R5.0

|

76

|

8.0

|

9

|

27

|

51

|

1700

|

13400

|

|

September 21

|

R5.5

|

75

|

8.6

|

9

|

25

|

48

|

1900

|

16300

|

|

October 5

|

R5.8

|

66

|

8.2

|

8

|

21

|

43

|

2300

|

18800

|

Corn development stage: Vn = nth leaf collar; R1 = Silking; R2 = Blister; R3 = Milk;

R4 = Dough; R5 = Dent;

R5.5 = 50% kernel milkline; R5.8 = 80% kernel milkline; R6

= Black layer (physiological maturity).

|

The following guidelines should be considered when deciding to harvest corn silage:

- Use kernel milk as a guideline for predicting when to begin silage harvest.

- To insure proper fermentation for the storage structure, accurate whole-plant moisture

must be determined. Immature corn is too wet to ensile and will seep out of the

storage structure lowering silage quality.

- In general, whole-plant moisture decreases at the rate of 0.5% per day during September.

- The relationship between kernel milk and whole-plant moisture differs among hybrids.

Within a hybrid the relationship between kernel milk and whole-plant moisture is

correlated regardless of environment.

- If there is more than one type of on-farm storage structure and since most hybrids

tend to be wetter than average around 50% kernel milk due to the stay-green trait,

producers may want to start by filling bunker silos and as the season progresses

move to other structures.

- To produce good quality silage with adequate yields, corn must be past the R4.5

to R5 stage of development. Corn which is immature should be fed to heifers or other

less productive animals.

Yield impact on frost-damaged corn grain

Yield losses are negligible if frost occurs when grain moisture is below 35 percent.

Yield loss is directly proportional to the stage of maturity and the amount of leaf

tissue killed. Those who will be advising growers about the likelihood of frost

damage and its impact on yield should get ready by consulting the

National Corn Handbook NCH-1 "Assessing Hail Damage to Corn" (Vorst,

1990). This publication has charts used by the National Crop Insurance Association

for assessing yield loss due to defoliation. Knowing how to recognize frost damage

and assess probable loss is important for decision making. An abbreviated

version of the loss chart is shown in Table 7. For example, corn that was defoliated

20% at the milk stage would have 3% yield loss.

|

Table 7. Estimated percent corn yield loss due to defoliation occurring at various

stages of growth.

|

|

Stage of growth

|

Percent leaf area destroyed

|

|

|

20

|

40

|

60

|

80

|

100

|

|

|

Yield loss (%)

|

|

Tassel

|

7

|

21

|

42

|

68

|

100

|

|

Silked

|

7

|

20

|

39

|

65

|

97

|

|

Blister

|

5

|

16

|

30

|

50

|

73

|

|

Milk

|

3

|

12

|

24

|

41

|

59

|

|

Dough

|

2

|

8

|

17

|

29

|

41

|

|

Dent

|

0

|

4

|

10

|

17

|

23

|

|

Black layer

|

0

|

0

|

0

|

0

|

0

|

|

derived from Vorst (1990)

|

The stem on a corn plant is a temporary storage organ for material that eventually

moves into the kernels (Afuakwa and Crookston, 1984).

Grain yield will continue to increase about 7 to 20% after a light frost that only

kills the leaves as long as the stem is not killed (Table 4).

Frost damaged grain drying rates

Freezing air temperatures sometimes occur in early autumn before grain

is physiologically mature. Grain drying rates can range from 0.83 to

1.16% moisture less/day (Hicks et al., 1976). Drying rates of grain

following leaf blade defoliation or moderate to severe cold treatments

are not different from the drying rate of normally maturing maize grain.

Husk condition does not affect grain drying rates. Defoliation and and

freezing before physiological maturity (R6) causes grain moisture levels

to be 2 to 6 percentage points greater than that of grain from control

plants when grain from control plants was in the 22 to 30% harvest

range. Grain frozen before R6 required 4 to 9 additional days of field

drying to reach the 22 to 30% moisture range. Defoliation and cold

treatments have little effect on the drying rates of cobs and ears, but

moisture levels are greater than those of the control. Loose husks cause

faster cob and ear drying compared to normal husks.

Characteristics of frost-damaged corn grain (from Hurburgh et

al., 2007).

- Small, misshapen, soft kernels

- Undeveloped starch structure; pithy kernels

- Test weights progressively below 52 lb./bu., depending on maturity

(in 1993, some corn was less than 40 lb./bu.)

- Average protein (7.5 to 8.0 percent) in corn heavier than 45

lb./bu., lower protein in corn lighter than 45 lb./bu.

- High breakage susceptibility; many fines generated in handling

- Lower digestibility compared with normal corn, especially for test

weights below 45 lb./bu.

- Little or no increase in test weight after drying

- Variable amino acid levels

- Mositure meters generally read low in immature corn. Surface drying

of kernels, giving deceptively low (by 1 to 2 percent) moisture readings

on dried corn

Recognize that these effects are progressive, with least impact on corn

closer to maturity.

Uses for frost-damaged corn

Animal feed is the best use for frost-damaged corn. Low test weight corn

used for large animal feed is only slightly less valuable (2 to 5

percent) than normal corn on a per-pound basis. Poultry, however, with

limited volumetric capacity, may be more sensitive to frost-damaged corn

than larger livestock.

Before feeding, test light corn for protein level, amino acid level, and

mycotoxins (especially fumonisin and vomitoxin). Composition will vary.

Be aware that fungi invade stressed corn more readily than they do

normal corn.

Wet, dry milling, and dry grind ethanol operations will not want

frost-damaged corn. Using frost-damaged corn in wet milling causes low

starch yields, and the separation of starch and protein cannot be clean.

In dry milling, frost damaged corn sharply reduces yields of dry mill

grits. Processors will discount light corn more heavily than its

reduction in feed value. Fermentation will be more variable in ethanol

production, with lower yields and less predictable distillers grain

quality.

Handling and storage of frost damaged grain

Immature and frost-damaged corn will have marginal quality, so it's

important to manage equipment carefully to minimize further quality

degradation. Set combines carefully, to balance the need to get small

kernels with kernel damage. Manage the fines and chaff, which can

increase mold problems in storage. Dry grain to uniform moisture levels,

a tricky business because harvest moisture is likely to be somewhat

uneven after a cold, short growing season. Dry frost-damaged corn at

reduced air temperatures (below 160 °F) and store at 14 percent (or

lower) moisture. Dry corn as gently as possible, even if it is tempting

to crank it up for higher dryer capacity. Also, use slow cooling methods

after gas-fired drying to minimize quality problems. If possible, aerate

stored grain to cool it to 20 to 30F for winter storage (in the upper

Midwest).

Frost-damaged corn breaks easily and goes out of condition quickly, even

at low moisture levels. Expect storage life to be about half as long as that of normal corn. Do

not harvest through low-lying frost damaged areas. The mixture will be a

high storage risk. Harvest and handle them separately.

Because immature corn kernels dry on the surface, expect the moisture

level of stored corn to be higher than test results. Expect to aerate

the stored corn frequently. Move immature corn to market before summer.

Store only clean corn and pull out the fines-laden center core of grain

in bins.

Further Reading

Abendroth, L.J., R.W. Elmore, M.J. Boyer, and S.K. Marlay. 2011. Corn

growth and development. PMR1009. Iowa State University.

Afuakwa, J. J. and R. K. Crookston. 1984. Using the kernel milk line to visually

monitor grain maturity in maize. Crop Sci. 24:687-691.

Burger, B.A., and .D. Hudelson. 1993. Effect of maturity on silage yield and quality.

In E.S. Oplinger (ed.) Wisconsin Research Report of studies on cultural practices

and management systems for agronomic crops. pp. 143-144.

Carter, P.R. 1991. Corn development and growing degree days. Agronomy Advice Mimeo

Series 28.10.

Carter, P.R. 1995. Late-Spring Frost

and Postfrost Clipping Effects on Corn Growth and Yield. Journal of Production Agriculture 8:203-209.

Carter, P.R., and O.B. Hesterman. 1990. Handling corn damaged by autumn

frost. Available at

http://www.ces.purdue.edu/extmedia/NCh/NCH-57.html.

Purdue University.

Hicks, D.R., G.L. Geadelmann, and R.H. Peterson. 1976. Drying Rates of

Frosted Maturing Maize. Agron. J. 68:452-455.

Hicks, D.R. 2004a. Corn test weight changes during drying. Available at

http://www.extension.umn.edu/cropenews/2004/04MNCN29.htm. University

of Minnesota.

Hicks, D.R. 2004b. The corn crop - frost and maturity. Available at

http://www.extension.umn.edu/cropenews/2004/04MNCN28.htm. University

of Minnesota.

Charles R. Hurburgh, C.R., R. Elmore and P. Pedersen. 2007. Frost Damage to Corn and Soybean.

PM 1635:

http://www.extension.iastate.edu/publications/PM1635.pdf.

Lauer, J.G. 1997. Corn replant / late-plant decisions

in Wisconsin. University of Wisconsin Extension. Bulletin A3353.

Lauer, J.G., and K.D. Hudelson. 1994. Effect of maturity on silage yield and quality.

In E.S. Oplinger and J.G. Lauer (ed.) Wisconsin Research Report of studies on cultural

practices and management systems for agronomic crops. pp. 359-360.

Mitchell, V.L., and R.W. Larsen. 1981. Growing degree days for corn in Wisconsin.

UWEX. 22 pp.

Neild, Ralph and James Newman. 1990. Growing Season Characteristics and

Requirements in the Corn Belt.

http://www.agcom.purdue.edu/AgCom/Pubs/NCH/NCH-40.html.

Nielson, R.L. 2002. Risk of fall frost injury to immature corn grain.

Available at

http://www.agry.purdue.edu/ext/corn/news/articles.02/Grain_Maturation_Frost-0910.html.

Purdue University.

Nielsen, R.L. 2002. Grain Fill Stages in Corn.

http://www.kingcorn.org/news/articles.02/Grain_Fill-0723.html

Peterson, P., J. Linn, and D. Hicks. 2004. Harvesting immature corn and

soybeans for forage after a killing frost Available at

http://www.extension.umn.edu/cropenews/2004/04MNCN23.htm.

Ritchie, W., J. J. Hanway, and G. O. Benson. 1993. How a corn plant develops.

Iowa State University CES Special Report No. 48. 21 pp.

Roth, G., D. Undersander, M. Allen, S. Ford, J. Harrison, C. Hunt, J. Lauer, R.

Muck, and S. Soderlund. 1995. Corn silage production, management, and feeding. American

Society of Agronomy, Madison, WI. 42 pp.

Stordahl, J. and G. Krause. 2004. Check corn silage for nitrates

Available at

http://www.extension.umn.edu/cropenews/2004/04MNCN30.htm.

Undersander, D.J., W.T. Howard, and R.D. Shaver. 1993. Milk per acre spreadsheet

for combining yield and quality into a single term. J. Prod. Agric. 6:231-235.

Vorst, J.V. 1990. Assessing hail damage to corn. Available at

http://www.ces.purdue.edu/extmedia/nch/nch-1.html.

Purdue University.

Wiersma, D.W., P.R. Carter, K.A. Albrecht, and J.G. Coors. 1993. Kernel milkline

stage and corn forage yield, quality, and dry matter content. J. Prod. Agric. 6:

94-99.

Wilcke, B. 2004. Drying, handling, and storing wet, immature, and

frost-damaged corn Available at

http://www.extension.umn.edu/cropenews/2004/04MNCN22.htm.